Waterproof polyethylene (PE) tarps are widely used across various industries due to their durability and versatility. This article will detail the applications, usage, and maintenance of PE tarps, focusing on their advantages for small processing factories. We’ll also highlight the high-quality products and customization options provided by the renowned manufacturer, LuckyTarps.

Introduction

Small processing factories often face dual challenges when selecting raw materials: durability and cost-effectiveness. Waterproof polyethylene tarps, with their high strength and multifunctionality, become the ideal choice for these factories. Whether producing tents, canopies, or waterproof covers, PE tarps meet various needs. However, understanding how to select and use this material correctly is crucial for enhancing production efficiency and reducing costs.

Waterproof polyethylene tarps are favored by small processing factories for their high strength, durability, and waterproof performance.

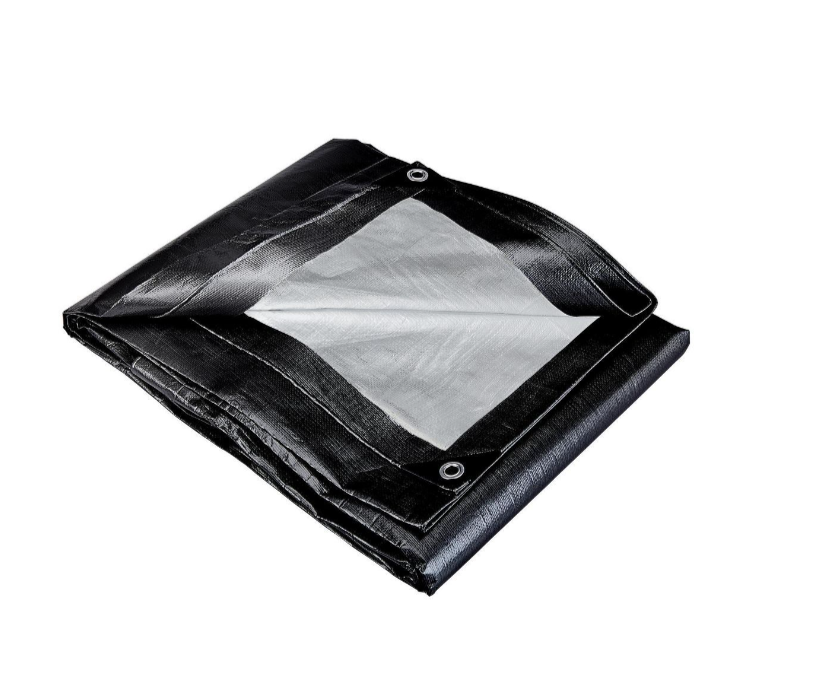

Waterproof polyethylene tarps,made from high-density polyethylene (HDPE) and low-density polyethylene (LDPE), are double-coated materials known for their waterproof, durable, and customizable properties, making them ideal for small processing factories to produce various finished products.

Their reinforced edges and grommet design ensure high performance in various harsh environments.

Applications of Waterproof Poly Tarp

Uses in Small Processing Factories

Waterproof polyethylene tarps have a wide range of uses in small processing factories. Here are some primary applications:

-Tents: Used to make various outdoor tents, their waterproof performance and durability ensure the tents remain dry and stable under different weather conditions.

– Canopies: Suitable for producing canopies that offer UV protection and extended lifespan.

– Waterproof Covers: Used to create various waterproof covers, protecting equipment and items from rain and dust.

Customization Options

Small processing factories need flexible materials to meet diverse customer demands. Waterproof polyethylene tarps offer various customizable options:

– Sizes: Available in different sizes to fit various application scenarios.

– Colors: Multiple color options, including double white, double blue, double silver, blue orange, double black, black/white, blue/white, stripes, and accepted customization, to meet different aesthetic requirements.

– Material Thickness: Ranges from 80gsm to 350gsm (3.5 to 12 oz/sq yd), suitable for different strength requirements.

– Treatment Processes: Includes UV protection and customizable printed logos to enhance product value and brand image.

Quality Advantages

The quality advantages of waterproof polyethylene tarps make them popular in small processing factories:

– Durability: Made from high-density polyethylene fibers, these tarps have excellent tear resistance and wear resistance.

– Waterproof Performance: Double-coated with low-density polyethylene, ensuring the material remains waterproof in harsh weather conditions.

– UV Resistance: Special UV protection treatment extends the lifespan of the material.

Usage and Maintenance Instructions

To ensure the optimal performance and longevity of PE tarps, here are some usage and maintenance tips:

– Applying Stitching Glue: For new PE tarps, apply an additional layer of waterproof stitching glue along the seams to ensure they remain waterproof during production and transit.

– Maintaining Dryness: Always keep the tarp dry. After use, hang it up to air dry. If dirty, gently wash with cold water without using harsh chemicals or vigorous scrubbing to protect the waterproof coating.

– Preventing and Handling Mold: To prevent mold damage, which compromises waterproofing, gently clean any mildew spots with a sponge dipped in a little detergent.

– Care During Use: Avoid stepping on the PE tarpaulin with shoes as this can weaken the fabric’s strength.

– Maintenance Instructions:Avoid using corrosive materials on the PE tarpaulin. Clean off any debris from the surface after use. Store the tarpaulin in a cool, indoor area to prolong its life. Do not place heavy objects on the tarpaulin; store it neatly in a warehouse corner to prevent damage.

LuckyTarps Company Profile

LuckyTarps excels in tarp manufacturing, with advanced machinery and 22 years experiences to produce the finest quality tarps available in attractive colors and qualities. These tarps are crafted from woven high-density polyethylene fibers, which are made by circular loom machines, warp x weft, and laminated on both sides with low-density polyethylene coating, ensuring durability and flexibility.

The reinforced edges and grommets enhance strength and ease of use, making these sheets or rolls ideal for long outdoor usage in all climates.

Highly recommended for family shelter protection, these tarps are puncture-resistant, flame retardant, and shrink-proof, proved to be an excellent choice for the truck tarp industry and various packaging needs.

LuckyTarps manufactures high-density polyethylene fabrics with widths of different inches and lengths of 6, 8, 10, and 12 feet.

The denier and the mesh are tailored according to customers’ demand.

LuckyTarps provides 3-ply and 5-ply tarpaulin solutions, customized depending on the requirements for waterproofing and sheltering trucks, wagons, ships, greenhouses, open storage materials, and buildings.

Customized depending upon individual customer requirements for size, color, and GSM. Our woven fabrics are tested for putrefaction, resistance to chemicals, and most importantly, they do not influence the taste or odor of contents within, confirming their suitability for varied applications, including food packaging.

Also tested for stress and strain bearing capacity.

Our factory spans over 20,000 square meters with a team of 300 people, including 5 senior engineers, and junior technical staff of nearly 11 people. Equipped with 100 circular loom machines, 8 plastic double-die wire drawing machines, and 4 laminating machines, enabling large-scale production without compromising quality. Benefit from our low minimum order quantities, with the ability to fulfill bulk orders within 20 days, and the availability of free samples for evaluation. Our PE tarps are available in weights ranging from 80 to 350 GSM.

FAQ:

Here are some related common questions and their answers:

– What is the difference between a poly tarp and a tarp?

Poly tarps are made from polyethylene, making them lightweight, waterproof, and resistant to tearing and UV rays.

– What is the most waterproof tarp?

Vinyl tarps are among the most waterproof options, known for their durability and versatility in various applications.

– What is the difference between tarp and tarpaulin?

Tarp is usually lighter and not coated, while tarpaulin is heavier and often made from canvas or another thick material that’s been treated with a waterproof coating.

– Is a poly tarp waterproof?

Yes, poly tarps are water-resistant and are often used for landscaping purposes due to their thickness and durability.

Related search keywords:

– Customizable waterproof poly tarp sheet for small processing factories near

– Best customizable waterproof poly tarp sheet for small processing factories

– Custom tarp with logo

– Custom waterproof tarps

– Custom tarps for patios

– Best Heavy Duty Waterproof tarps

Conclusion

Waterproof polyethylene tarps, with their versatility and durability, are the ideal choice for small processing factories. By following proper usage and maintenance instructions, their lifespan and efficiency can be maximized. LuckyTarps offers high-quality, customizable tarps that meet various application needs, making them a reliable partner for your business.

—