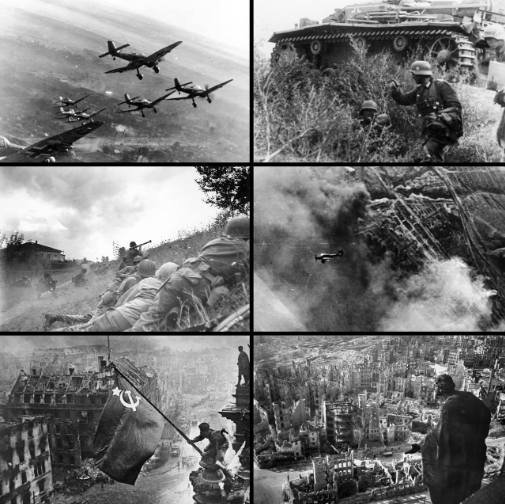

During World War II, the world was desperately searching for materials that would improve communications technology.

At that time, a new type of material was discovered that was not only lightweight but also low-cost. This was polyethylene (PE).

Polyethylene was originally synthesized accidentally by British chemists who discovered a white, waxy substance in their experiments that had excellent insulating properties and chemical stability.

Due to its properties, polyethylene was soon used to make the insulation layer of radar cables, greatly improving the performance of Allied radar and helping them gain a tactical advantage in the war.

After the war, with the arrival of peace, people began to explore the application of polyethylene in the civilian field. Not only is it lightweight and easy to process, it is also resistant to corrosion by most acids and alkalis, making it an ideal packaging material.

Over time, polyethylene began to play a key role in a variety of everyday products. From plastic bags and water bottles to medical devices, polyethylene has become a darling of the plastics industry because of its durability and recyclability.

Today, polyethylene is not only the most produced plastic in the world, it continues to drive innovation, such as being used to make lighter car parts and longer-lasting construction materials.

However, with the surge in the use of polyethylene, its environmental impact has gradually become the focus of public attention. The world is beginning to look for ways to recycle and reuse polyethylene, thus reducing its impact on the environment. Many innovative teams and scientists are developing new technologies to enable efficient recycling and reuse of polyethylene, as well as exploring bio-based alternatives that can break down more easily in ecosystems.